Packaging Machines

Discover Didamak’s Versatile Range of Packaging Machinery

At Didamak, we take pride in offering a comprehensive selection of top-quality packaging machines

Horizontal 4-Side Seal Sachet Machine

Perfect for secure and visually appealing packaging, this machine is ideal for a wide range of products, including condiments, sauces, and liquids.

Vertical Powder and Granule Packaging Machine

Our vertical packaging machine provides efficient and precise filling and sealing for powders and granules in vertical pouches.

Bottle and Jar Filling Machines

Ensure accurate and consistent product filling with our bottle and jar filling machines, suitable for liquids, creams, and granules.

Optional Equipments

These supplementary tools include conveyors for smooth material flow, tanks for efficient bulk material storage, semi-automatic machines for versatile packaging, hoppers for controlled material feeding, automatic screw feeders for precision, and mixers/blenders for uniform mixing.

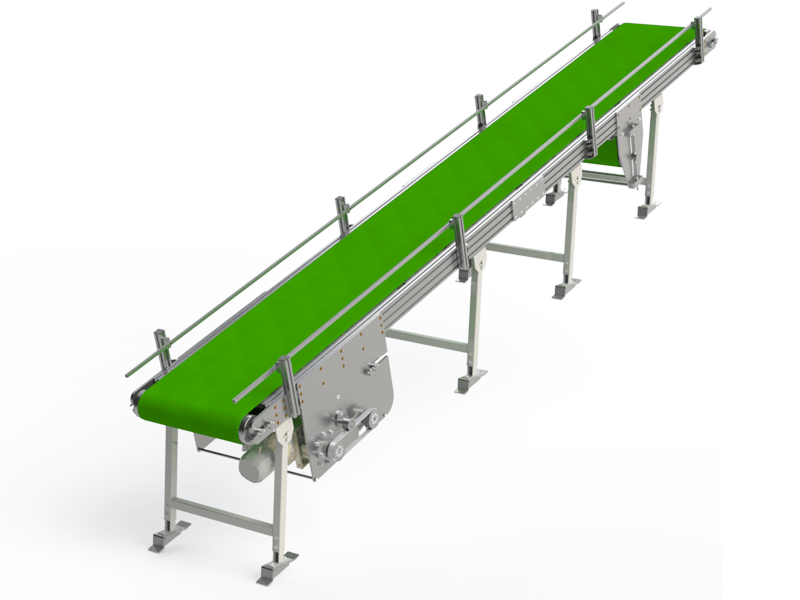

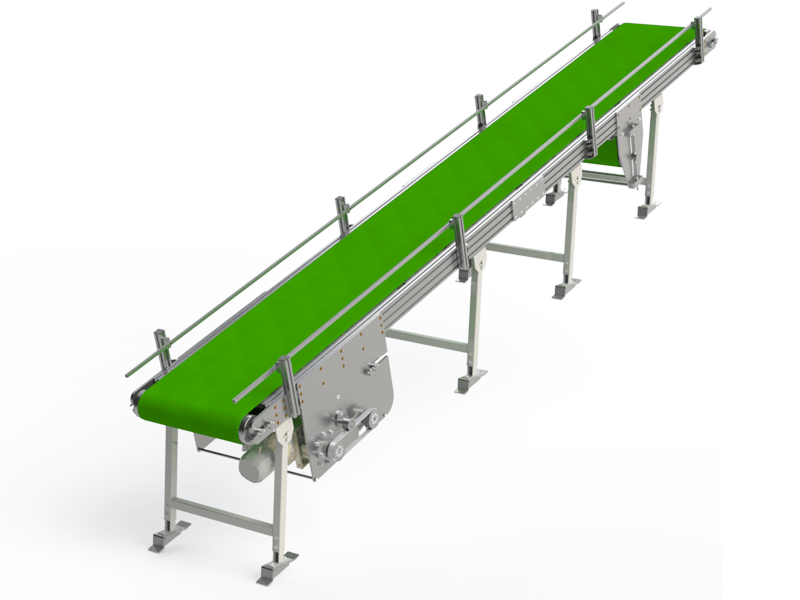

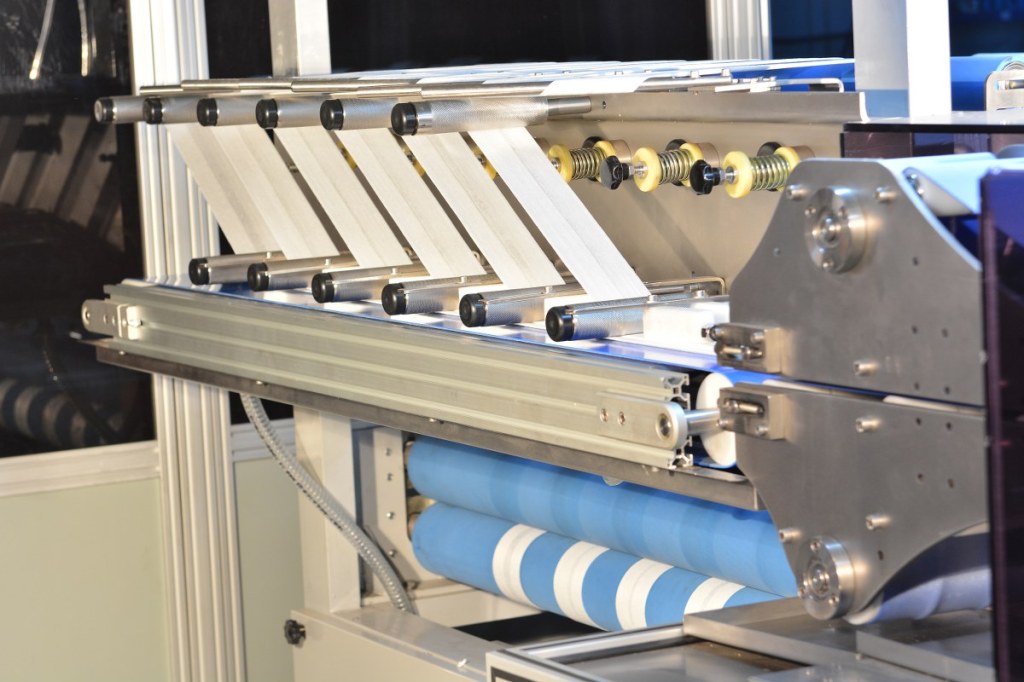

Conveyor Systems

It is used in the process of transferring products from one place to another. Various conveyors such as Modular Belt, Stainless Modular Belt, PVC Belt, Timing Belt, Chain Pallet Conveying, and Idler Belts are used in transport systems according to their suitability for the product.

DM-H500 Horizontal Packaging Machine

The DM-H500 horizontal packaging machine is designed for the efficient packaging of various products, including powder, granules, liquids, and pastes, in 3 or 4 side-sealed sachets.

Category: Horizontal Sachet Machines

Description

The DM-H500 horizontal packaging machine, is specifically engineered to package a wide range of products, such as powder, granules, liquids, and pastes, into sealed sachets with either three or four sides.

Starting from a reel of heat-sealable material, the film is meticulously folded into a “V” shape. Through intermittent motion, the machine expertly forms individual sachets and precisely cuts them. These sachets are then transported to subsequent stations, which include opening, filling (with 2-3 stations for flexibility), and sealing.

The dosage for filling the sachets can be tailored to match the specific product:

- Auger dispenser for powdered products.

- Volumetric dispenser for granulated products.

- Dosing unit for liquids or pastes.

Technical Specifications + Sachet Types and Sizes

| Model | DM-H500 Simple | DM-H500 Duplex |

|---|---|---|

| Speed | 100 spm | 200 spm |

| Minimum Pouch Size | 70×90 mm | 50+50×90 mm |

| Maximum Pouch Size | 140×200 mm | 70+70×200 mm |

| Volume | 5 to 250 cc | 5 to 90 cc |

| Electrical Consumption | 2.5 KW | 3.5 KW |

| Reel Dimensions | Ø Max = 450mm | Ø Max = 450mm |

| Anch. Max = 400mm | Anch. Max = 400mm |

The DM-H500 horizontal packaging machine offers precise and efficient packaging solutions for your product needs.

DM-V300 Multi Fully Automatic Packaging Machine

The DM-V300 Multi Fully Automatic Packaging Machine is an advanced packaging solution that offers exceptional performance and precision. With its multi-head scale system and versatile features, it ensures efficient and accurate packaging for a wide range of products.

Key Features

- Multi-Head Scale System: The machine features a multi-head system scale unit that can be adjusted to 10, 14, 18, or 24 scales, depending on the product and desired weight in grams. This flexibility allows for precise and customized packaging.

- Wide Product Compatibility: The multi-head scale system effortlessly handles challenging products such as dried fruits, nuts, pasta, dried grapes, and salads. Its advanced technology ensures consistency and accuracy even for difficult-to-package items.

- Sturdy Construction: The main chassis of the machine is constructed from a single 6mm thick frame, ensuring stability and durability during operation. This solid foundation supports reliable and long-lasting performance.

- Pneumatic or Servo Systems: The packaging unit system is designed with pneumatic or servo systems, providing smooth and efficient operation. A pneumatic shaft pin is used for the packing assembly roll, ensuring secure and reliable packaging.

- Food-Safe Materials: All materials used in the scale and packaging unit are made of 304 stainless steel, guaranteeing food safety. This high-quality construction ensures hygienic packaging, adhering to the strictest industry standards.

- Independent Scale and Packaging Units: The independent operation of the scale unit and packaging unit minimizes weight errors, enabling precise and consistent weight measurements. This separation enhances overall efficiency and accuracy.

- Enhanced Scale Capacity: The multi-head scale system has the capability to handle more packets compared to other scale systems, maximizing productivity. It is designed to meet the demands of high-volume packaging operations.

- Customizable Printing: The machine includes a numbering system that allows easy customization of the “Manufacturing and Expiry Date” on each packet. This feature ensures clear and accurate product information for consumers.

Technical Specifications

| Machine Size | Working Range (10 Scales) | Capacity (10 Scales) | Electric Power | Air Pressure | Energy Consumption |

|---|---|---|---|---|---|

| Width: 2300 mm | 0-1000 grams | 40-60 packets/min | 380V-50Hz | 6-8 Bar | 3 Kw/h |

| Length: 2500 mm | – | – | – | – | – |

| Height: 4000 mm | – | – | – | – | – |

The DM-V300 Multi Fully Automatic Packaging Machine is a reliable and efficient solution for your packaging needs. Its versatility, precision, and advanced features ensure high-quality packaging for a variety of products. Trust in the DM-V300 to streamline your packaging process and deliver outstanding results.

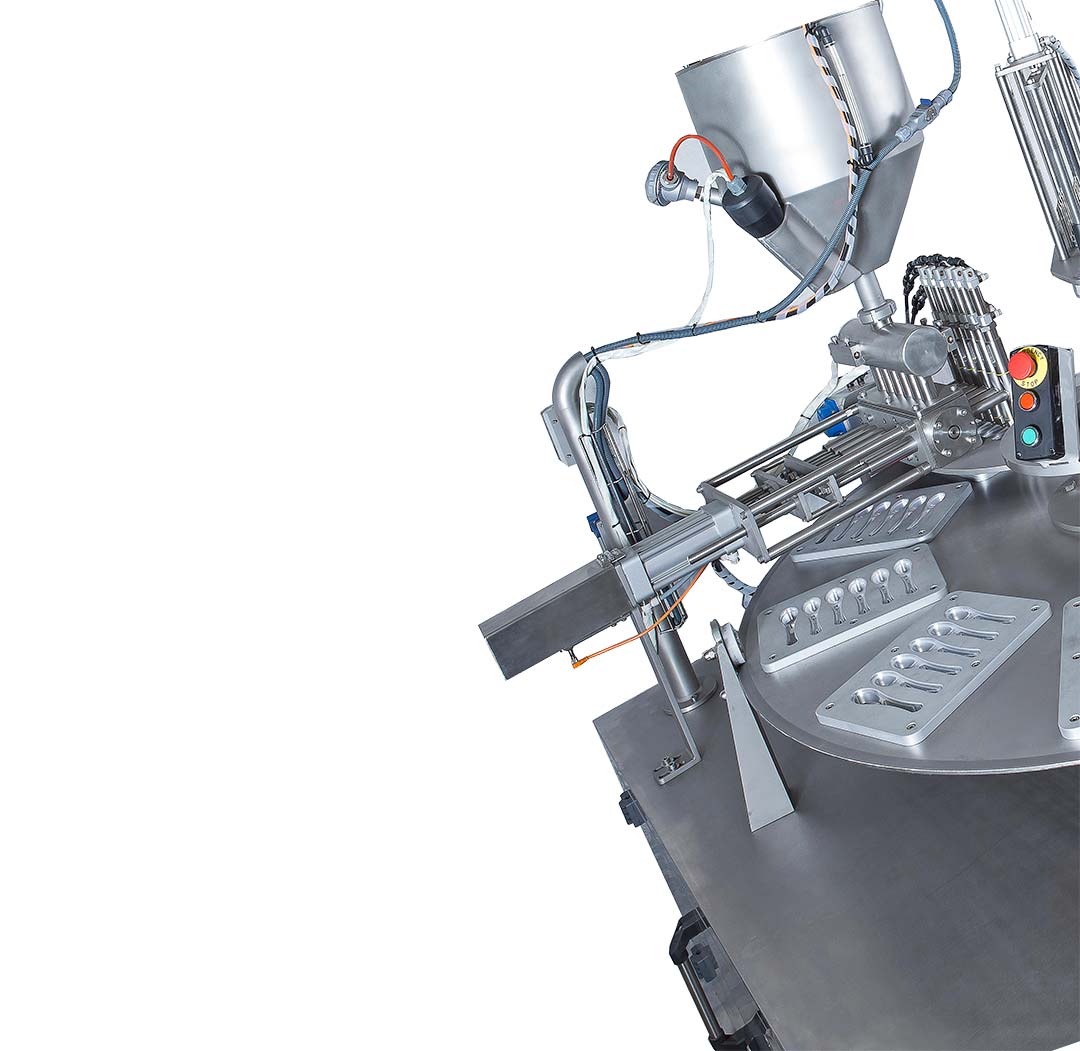

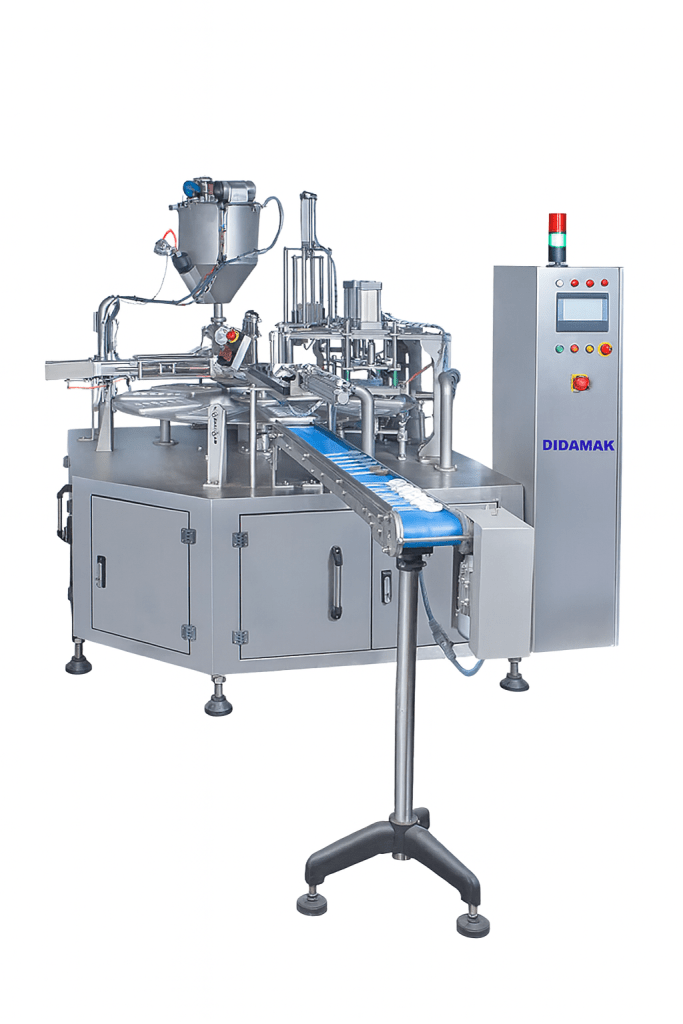

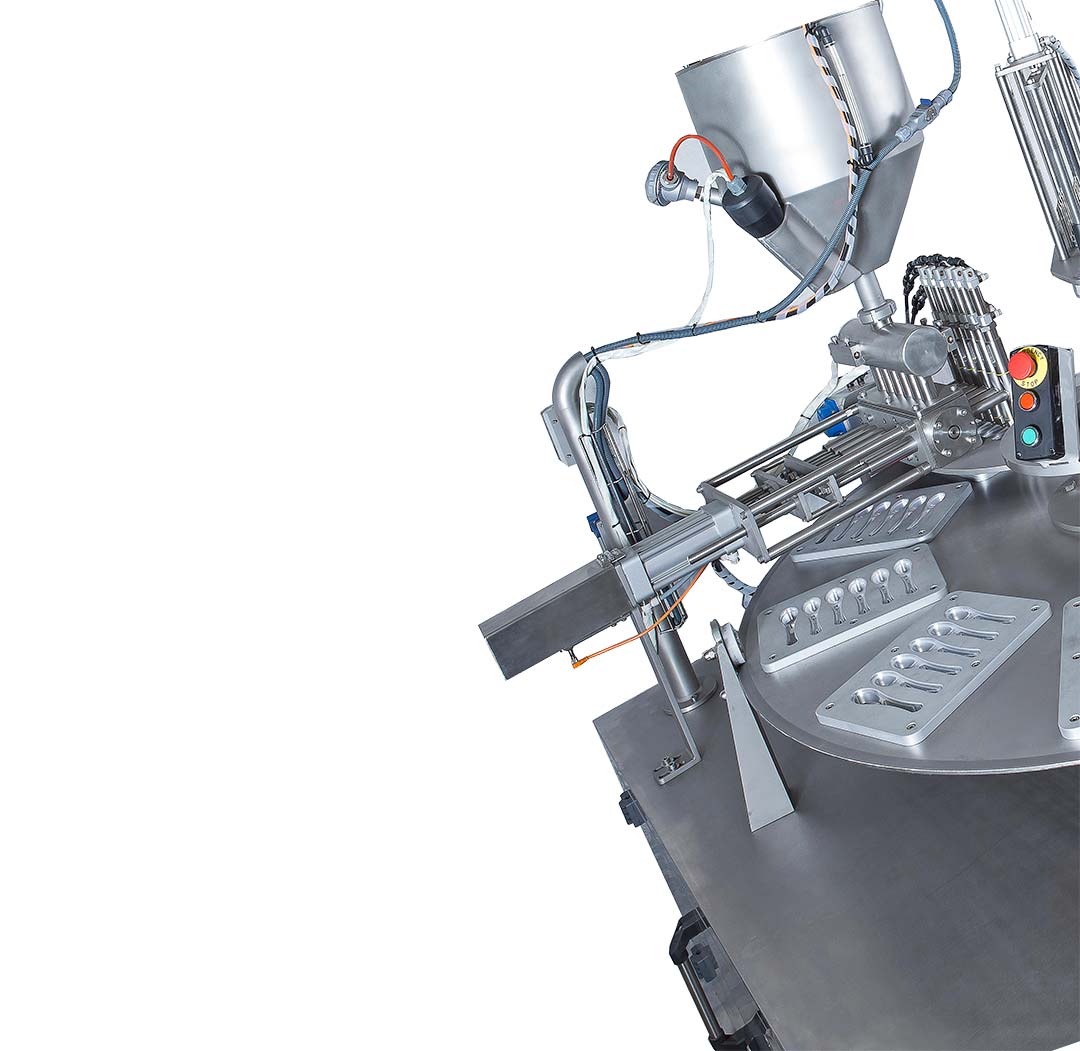

6-Compartment Spoon Honey Filling and Labeling Machine

The 6-Compartment Spoon Honey Filling and Labeling Machine is a versatile and efficient solution for filling and labeling plastic spoons with various products such as honey, chocolate, jam, and more. This machine streamlines the production process and ensures high-speed filling.

How does the spoon honey filling and labeling machine work?

The spoon honey machine consists of 6 nozzles, and the capacity and number of nozzles can be customized to meet your specific production needs. Our engineers will design a machine tailored to your desired capacity, allowing you to choose the configuration that best suits your requirements.

The filling process starts at the feeding station, where plastic spoons are automatically transported to the filling station. At the filling station, the spoons are filled with your desired product. Whether it’s honey, chocolate, jam, or other liquid or powdered products, the machine accurately fills each spoon.

After the filling station, the spoons move to the lid sealing station. Here, aluminum foil is securely placed on the spoons to ensure proper sealing. Once the sealing process is completed, the filled and sealed spoons are ready for the next step.

At the exit station, you can retrieve the finished products. They are ready for packaging, allowing you to efficiently distribute and sell your filled and labeled spoons.

| Spoon Honey Filling, Sealing, and Labeling Machine |

|---|

| Capacity |

| 6,500 Pieces/hour (Pcs/H) |

| Products that can be filled |

| Honey, Chocolate, Jam, Marmalade, Milk, Sugar, Salt, Spices, Powdered Products |

| Filling Weight |

| Adjustable according to desired weight. |

| Number of Filling Nozzles |

| 6 |

| Pneumatic Pressure Requirement |

| 8 bar |

| Materials Used |

| 304 – 316 quality food-grade stainless steel |

| Optional Technical Features |

| – UV lamp |

| – HEPA filter |

| – Plastic lid sealing |

| – Filling in different bowl shapes |

| – Different size filling attachments in one machine |

| – 2nd filling station |

| – Roll cutting and sealing |

| – Ready-cut foil sealing |

| – Solid or liquid nozzle option |

| – Funnel heater and mixer |

| – Collection tray for the output conveyor |

| – Transfer pump to the filling unit |

| – Nitrogen gas |

| Spoon Honey Capacity |

| – 1 Nozzle: 1,200 Pieces/hour (Pcs/H) |

| – 2 Nozzle: 2,400 Pieces/hour (Pcs/H) |

| – 3 Nozzle: 3,300 Pieces/hour (Pcs/H) |

| – 4 Nozzle: 4,200 Pieces/hour (Pcs/H) |

| – 5 Nozzle: 5,400 Pieces/hour (Pcs/H) |

| – 6 Nozzle: 6,500 Pieces/hour (Pcs/H) |

| Remote Troubleshooting |

| We offer remote solutions to address any issues you may encounter with the Spoon Honey Filling Machine. Our automation partner, GMT, a domestic manufacturer, relies on PLC, HMI, servo motors and drives, speed control devices, and power supplies. Our machines are designed to be compatible with Industry 4.0 standards, allowing for remote monitoring and control, which is an essential feature for ensuring high-quality production. The ability to connect to the PLC remotely via the internet and control it provides us with a more systematic infrastructure. With this capability, we can instantly intervene in any issues that may arise, ensuring uninterrupted operation of our machines. |

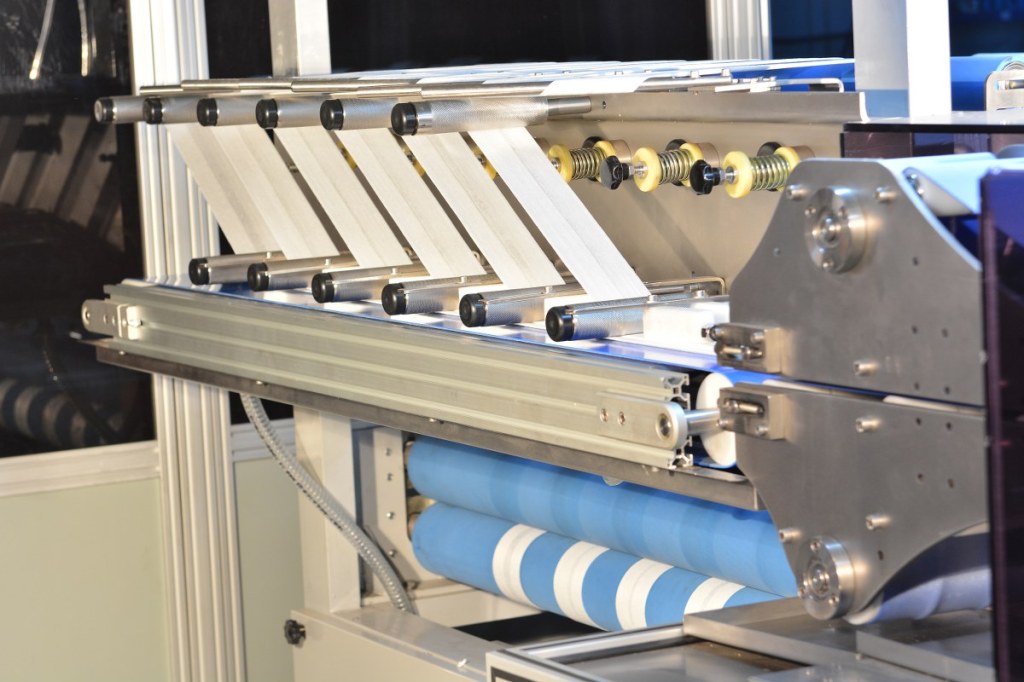

DM-W700 – 2 dual-channel

The DM-W700 – 2 dual-channel fully automatic wet tissue and makeup remover tissue machine line is a technologically advanced production system designed to efficiently manufacture wet pocket tissues and makeup remover wipes. This machine line is equipped with two channels to enhance productivity while ensuring the highest quality standards.

Technical Specifications:

- Model: DM-W700 – 2

- Dual-Channel Design: The machine line features two channels, allowing for simultaneous production and increased output.

- Wet Tissue Production: It is capable of producing wet pocket tissues and makeup remover wipes with precision and accuracy.

- Automatic Operation: The machine line operates fully automatically, minimizing the need for manual intervention and improving operational efficiency.

- High Speed: It is designed to achieve high production speeds, optimizing productivity.

- Customizable Settings: The machine line’s settings can be easily customized to meet specific production requirements.

- Reliable Performance: With advanced technology and sturdy construction, it delivers reliable and consistent performance.

- Compact Design: The machine line is compact in size, occupying minimal space in the production facility.

- Easy Maintenance: It is designed for easy maintenance and cleaning, ensuring smooth operation and reducing downtime.

The DM-W700 – 2 dual-channel fully automatic wet tissue and makeup remover tissue machine line is the perfect solution for businesses seeking efficient and cost-effective production of wet pocket tissues and makeup remover wipes. It combines advanced features, high-speed operation, and customizable settings to meet the demands of modern manufacturing processes.

Full Automatıc Continuous Cutting

Our continuous cutting shrink machines are designed to efficiently cover all of your products with PVC or Polyolefin (POF) packaging. The use of PLC control ensures quick and smooth operation, with the flexibility to integrate easily into production lines. Temperature and position settings can be easily customized and stored, allowing for precise prescription. Moreover, the temperature controls can be accurately adjusted from the screen, and the P.I.D. can be set in a controlled manner. With safety sensors and working photocells, product packaging is carried out in a secure manner. The machine’s mechanical and electrical safety production complies with CE directives, providing added peace of mind.

Technical Specifications

- Operator Control System: 7” Touch PLC Screen

- P.I.D. Bonding is provided by Electronic Temperature Control System.

- Capacity: 25-40 Packs / Min. (According to product size)

- Film drive mechanism with lower and upper motor

- Adjustable tunnel conveyor speed

- All electrical cables inside the tunnel are non-combustible external shielded cables.

- Required air pressure: 5 – 6 bar

- Electricity: 380 V. 50-60 Hz. 3 Ph

- The machine is installed on site by our assembly team, given working training and delivered with usage and maintenance instructions.

- Machines – 2 YEARS – guaranteed.

Packaging Machines

Discover Didamak’s Versatile Range of Packaging Machinery

At Didamak, we take pride in offering a comprehensive selection of top-quality packaging machines.

Horizontal 4-Side Seal Sachet Machine

Perfect for secure and visually appealing packaging, this machine is ideal for a wide range of products, including condiments, sauces, and liquids.

Vertical Powder and Granule Packaging Machine

Our vertical packaging machine provides efficient and precise filling and sealing for powders and granules in vertical pouches.

Bottle and Jar Filling Machines

Ensure accurate and consistent product filling with our bottle and jar filling machines, suitable for liquids, creams, and granules.

Optional Equipment

These supplementary tools include:

- Conveyors for smooth material flow

- Tanks for efficient bulk material storage

- Semi-automatic machines for versatile packaging

- Hoppers for controlled material feeding

- Automatic screw feeders for precision

- Mixers/Blenders for uniform mixing

Conveyor Systems

Used in the process of transferring products from one place to another, various types of conveyors such as Modular Belt, Stainless Modular Belt, PVC Belt, Timing Belt, Chain Pallet Conveying, and Idler Belts are selected based on product suitability.

DM-H500 Horizontal Packaging Machine

The DM-H500 horizontal packaging machine is designed for the efficient packaging of various products, including powder, granules, liquids, and pastes, into 3 or 4 side-sealed sachets.

Category: Horizontal Sachet Machines

Description: The DM-H500 is specifically engineered to package a wide range of products, such as powder, granules, liquids, and pastes, into sealed sachets with either three or four sides.

Starting from a reel of heat-sealable material, the film is meticulously folded into a “V” shape. Through intermittent motion, the machine expertly forms individual sachets and precisely cuts them. These sachets are then transported to subsequent stations, which include opening, filling (with 2-3 stations for flexibility), and sealing.

The dosage for filling the sachets can be tailored to match the specific product:

- Auger dispenser for powdered products.

- Volumetric dispenser for granulated products.

- Dosing unit for liquids or pastes.

Technical Specifications

| Feature | DM-H500 Simple | DM-H500 Duplex |

|---|---|---|

| Speed | 100 spm | 200 spm |

| Minimum Pouch Size | 70×90 mm | 50+50×90 mm |

| Maximum Pouch Size | 140×200 mm | 70+70×200 mm |

| Volume | 5 to 250 cc | 5 to 90 cc |

| Electrical Consumption | 2.5 KW | 3.5 KW |

| Reel Dimensions | Ø Max = 450 mm | Ø Max = 450 mm |

| Anch. Max = 400 mm | Anch. Max = 400 mm |

The DM-H500 horizontal packaging machine offers precise and efficient packaging solutions for your product needs.

DM-V300 Multi Fully Automatic Packaging Machine

The DM-V300 Multi Fully Automatic Packaging Machine is an advanced packaging solution that offers exceptional performance and precision. With its multi-head scale system and versatile features, it ensures efficient and accurate packaging for a wide range of products.

Key Features

- Multi-Head Scale System: The machine features a scale unit that can be adjusted to 10, 14, 18, or 24 scales, depending on the product and desired weight in grams. This flexibility allows for precise and customized packaging.

- Wide Product Compatibility: Effortlessly handles challenging products such as dried fruits, nuts, pasta, dried grapes, and salads, providing consistency and accuracy.

- Sturdy Construction: The main chassis is constructed from a single 6mm thick frame, ensuring stability and durability during operation.

- Pneumatic or Servo Systems: Designed for smooth and efficient operation, the packaging unit system includes a pneumatic shaft pin for secure packaging.

- Food-Safe Materials: Made of 304 stainless steel, ensuring hygienic packaging and compliance with industry standards.

- Independent Scale and Packaging Units: Minimizes weight errors, enhancing efficiency and accuracy.

- Enhanced Scale Capacity: Designed to handle more packets compared to other scale systems, maximizing productivity.

- Customizable Printing: Includes a numbering system for easy customization of manufacturing and expiry dates on each packet.

Technical Specifications

| Feature | Dimensions | Specifications |

|---|---|---|

| Machine Size | Width: 2300 mm | Capacity (10 Scales): 0-1000 grams |

| Length: 2500 mm | Speed: 40-60 packets/min | |

| Height: 4000 mm | Electric Power: 380V-50Hz | |

| Air Pressure: 6-8 Bar | ||

| Energy Consumption: 3 Kw/h |

The DM-V300 Multi Fully Automatic Packaging Machine is a reliable and efficient solution for your packaging needs, ensuring high-quality packaging for a variety of products.

6-Compartment Spoon Honey Filling and Labeling Machine

The 6-Compartment Spoon Honey Filling and Labeling Machine is a versatile and efficient solution for filling and labeling plastic spoons with products such as honey, chocolate, jam, and more. This machine streamlines the production process while ensuring high-speed filling.

How It Works

The spoon honey machine consists of 6 nozzles, with capacity customizable to meet specific production needs. Our engineers design machines to match your desired capacity and configurations.

The filling process initiates at the feeding station, where plastic spoons are automatically transported to the filling station. Here, spoons are accurately filled with the desired product, followed by a sealing process with aluminum foil.

Once sealed, the filled spoons move to the exit station for easy retrieval and further packaging.

Specifications

- Capacity: 6,500 Pieces/hour (Pcs/H)

- Products: Honey, Chocolate, Jam, Marmalade, Milk, Sugar, Salt, Spices, Powdered Products

- Filling Weight: Adjustable according to desired weight.

- Number of Filling Nozzles: 6

- Pneumatic Pressure Requirement: 8 bar

- Materials Used: 304 – 316 quality food-grade stainless steel

Optional Features

- UV lamp

- HEPA filter

- Plastic lid sealing

- Different size filling attachments

- Remote troubleshooting capability

The Spoon Honey Filling Machine is designed to integrate with Industry 4.0 standards for remote monitoring, ensuring high-quality production.

DM-W700 – 2 Dual-Channel Fully Automatic Wet Tissue and Makeup Remover Tissue Machine

The DM-W700 – 2 is a technologically advanced production system designed to efficiently manufacture wet pocket tissues and makeup remover wipes. Its dual-channel design enhances productivity while maintaining the highest quality standards.

Technical Specifications

- Model: DM-W700 – 2

- Automatic Operation: Fully automated, minimizing manual intervention for operational efficiency.

- High Speed: Achieves high production speeds.

- Customizable Settings: Easily adjusted per specific production requirements.

- Compact Design: Requires minimal space in production facilities.

- Easy Maintenance: Designed for straightforward maintenance and cleaning.

The DM-W700 – 2 is the perfect solution for businesses seeking efficient and cost-effective production of wet pocket tissues and makeup remover wipes, combining advanced features with high-speed operation.

Full Automatic Continuous Cutting

Our continuous cutting shrink machines are designed to efficiently cover products with PVC or Polyolefin (POF) packaging. Featuring PLC control for quick, smooth operation, they easily integrate into production lines.

Technical Specifications

- Operator Control System: 7” Touch PLC Screen

- Capacity: 25-40 Packs/Min. (depending on product size)

- Electricity: 380 V, 50-60 Hz, 3 Ph

- Safety: Complies with CE directives for mechanical and electrical safety.

Didamak remains committed to delivering innovative solutions and exceptional service, ensuring your packaging processes are efficient and reliable.